Panels and Profiles Cutting Optimization Software

OptiCut is a panels and profiles cutting optimization software, based on a powerful multimode, multiformat, and multimaterial algorithm.

– OptiCut features grain direction, trim cuts, plated edges and pre-cuts, stocks and reusable falls, panels turnaround, and parametric labels.

OptiCut’s import and export functions are compatible with all major spreadsheets (MicroSoft Excel, etc …), and with most cabinet design softwares (PolyBoard, TopWood, Obvie, KitchenDraw, etc …).

– OptiCut’s universal Post_Processor is compatible with most CNC saws.

– OptiCut is available in a multilingual version, and is used in over 30 countries.

Main features

Multimode Algorithm:

OptiCut is based on a powerful and parametric algorithm, with 6 predefined optimization modes (Fast, Standard 1 & 2, Advanced 1 & 2, and CNC optimized).

Only Advanced 1 and Advanced 2 modes enable panels turnaround.

Multi-Format and Multi-Material optimization:

OptiCut optimizes mixed materials cutting lists.

For each material, OptiCut takes into account all available panels formats.

Plated Edges and Pre-Cuts:

OptiCut identifies plated edges and their thicknesses, and displays either net (cutting) or finished (plated) dimensions. The edge fields may also be used to optimize pre-cuts.

Stocks and reusable falls follow-up:

OptiCut’s stock may be up-dated after each optimization. Falls above minimal dimensions are considered as reusable, and will be added to the stock with a depreciation factor.

Technical and financial Summary:

After each optimization, and as a complement to the cutting maps, OptiCut prints a global summary including :

– technical data, such as quantities, linears, and rates,

– optimization financial costs.

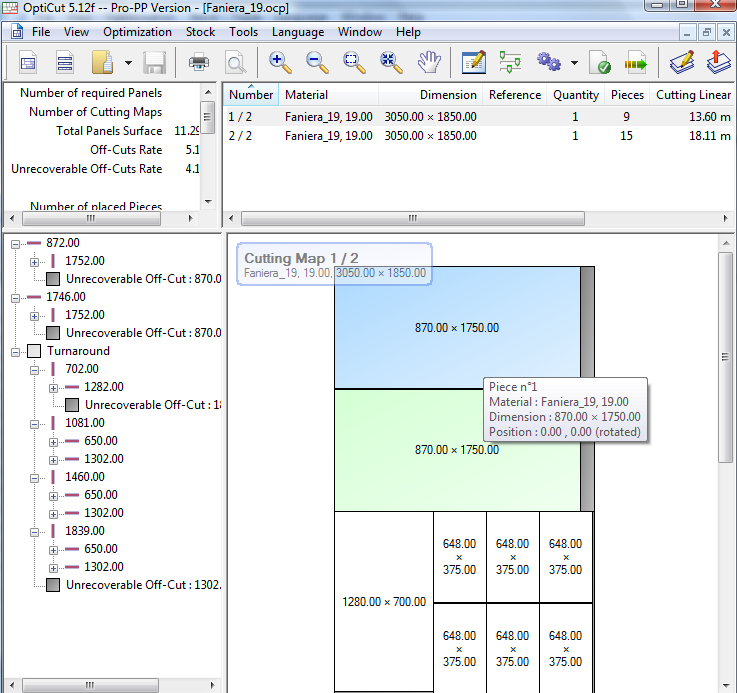

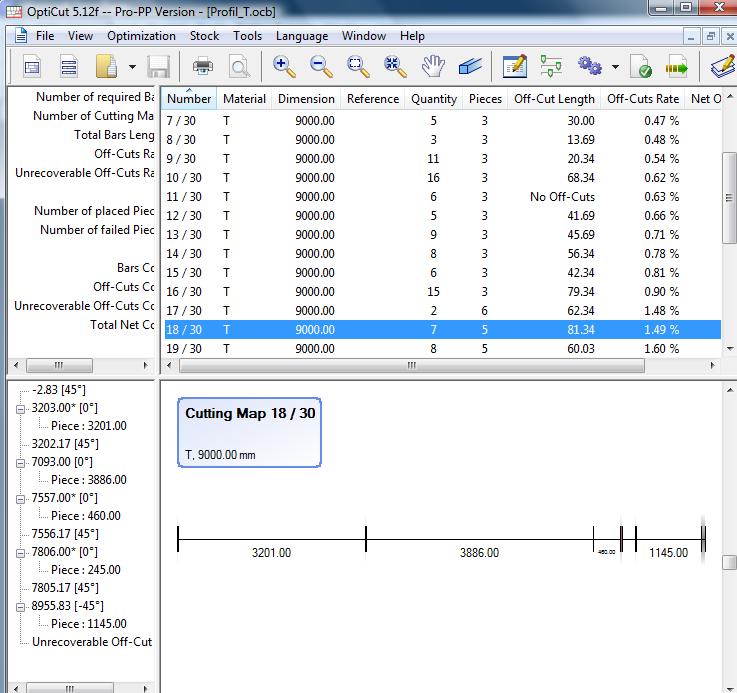

Profiles cutting optimization:

OptiCut optimizes also profiles cutting lists, using the same parameters as for panels.

OptiCut prints profiles cutting maps, as well as gobal summaries, and labels.

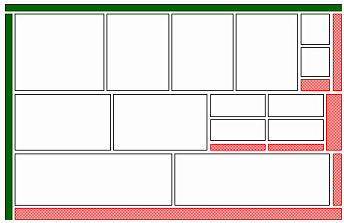

Panels turnaround:

The OptiCut turnaround function enables main cutting direction changes (horizontal or vertical) within the same cutting map.

Theses changes, which increase panel handling, also improve falls quality, and sometimes allow panels savings.

Post Processor and CNC Controls:

The OptiCut integrated Post_Processor function translates cutting maps into the main CNC saws languages and formats.

Examples of optimisation results, both for panels and bars.

Versions

OptiCut is available in several versions offering increasing capacities, starting from 50 pieces up to unlimited capacity (Versions Pro and Pro_PP).

– OC-50: Version limited to 50 pieces cutting lists.

– OC-200: Version limited to 200 pieces cutting lists.

– OC-500: Version limited to 500 pieces cutting lists.

– OC-Pro: Version unlimited in capacity.

– OC-Pro_PP: Version unlimited in capacity, with a Post_Processor function compatible with CNC saws.

Bars cutting lists are unlimited in all OptiCut 4 versions.

In OptiCut 5, Bars cutting lists are limited to 5 times the Panels capacity.

Downloads